[vc_row][vc_column][vc_column_text]

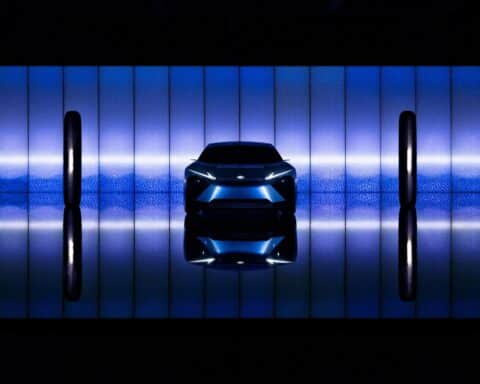

Louis Vuitton has just unveiled a futuristic version of its famous Tambour. Clearly stated objective : Perpetuate an icon of masculine watchmaking by combining avant-garde technologies with traditional fine watchmaking know-how.

Louis Vuitton watchmaking has just unveiled a futuristic version of its famous Tambour equipped with an imposing 46 mm case in titanium and carbostratum which welcome an exceptional skeleton-type gauge from the Fabrique du Temps with flying tourbillon.

As a result, the spectacular dimension of the movement is reinforced.

But for connoisseurs, the real feat results from the little Hallmark of Geneva which appears at 6 o’clock on the dial. A standard of excellence, emblem of fine watchmaking, established in 1886.

You should know that since the takeovers in 2011 of La Fabrique du Temps, able to design high-end gauges, then Léman Cadrans, the trunk maker, in search of legitimacy in the watchmaking field, has not stopped innovating.

The design of the future

Inspired by Möbius ribbon, the box is revisited, stretched, elongated.

Its convex camber inscribed in a circle turns out to be very consistent in its graphic approach to the future watchmaker.

The piece with a diameter of 46 mm deconstructs the round to become a full-blown shape : seen from the side, the middle has a continuous curve from one attachment to the other and, seen from above, it appears round.

“The ambition is to perfectly fit the natural curve of the wrist,” said the watchmaker in an official statement.

Another signature of the house, the LV initials, which sits right in the middle of the dial …

A high-flying watch

The Tambour Curve Flying Tourbillon Poinçon of Genève uses technical, ultra-light and resistant materials from aeronautics for its packaging.

The external part of the case is made of Carbostratum®, a unique composite material developed for Louis Vuitton.

Its production requires more than 100 layers of carbon of different sizes, applied randomly.

“The entire package is then pressurized to a regulated temperature,” explains Michel Navas, master watchmaker at La Fabrique du Temps Louis Vuitton. Once stabilized, this ultra-rigid material is then machined using latest generation multidimensional machines. It is during these operations that volumes appear with gentle curves and powerful at the same time, which make each model unique.”

The Hallmark of Geneva : watchmaking excellence

It should be remembered that the house inaugurated in 2014 a factory of nearly 5,000 square meters in Meyrin, a decisive location for the Poinçon of Genève.

Regarded as the most respected certification in terms of provenance, fine craftsmanship and reliability, the Poinçon of Genève demands perfection.

In 2016, the house won a first punch with the Voyager Tourbillon Volant Poinçon of Genève and a second, a year later, with the Tambour Moon Tourbillon Volant.

With the Tambour Curve Tourbillon Volant Poinçon de Genève, Louis Vuitton continues its anchoring in the very limited club of watchmaking companies holding this prestigious stamp.

More than 120 hours of movement work are required to reach this level of technical requirement.

Note that there is also a very bling-bling version with the LV, the flange, the crown and the horns all in diamonds.

Featured Photo : © Louis Vuitton

[/vc_column_text][/vc_column][/vc_row]